Maximizing Efficiency and Reliability with Diesel Generators for Parallel Operation

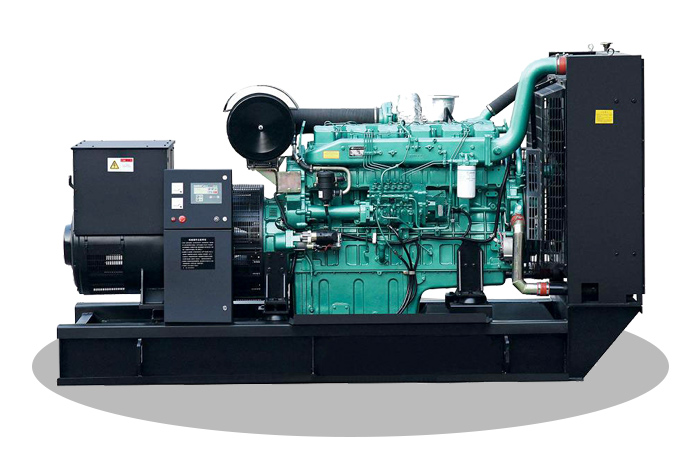

Introduction: In today's world, a reliable power supply is crucial for various industries, businesses, and institutions to function efficiently. Diesel generators have long been a popular choice for providing backup power during outages or as a primary power source in areas with unreliable grid power. One way to enhance the capability and efficiency of diesel generators is through parallel operation. This article will delve into the concept of diesel generators for parallel operation, exploring the benefits, considerations, and best practices associated with this setup. 1. Understanding Diesel Generators: Diesel generators are a type of power generation equipment that use diesel fuel to produce electricity. These generators consist of an engine, alternator, fuel system, cooling system, and control panel. The diesel engine drives the alternator, which converts mechanical energy into electrical energy. Diesel generators are known for their reliability, durability, and ability to provide consistent power output over extended periods, making them a popular choice for various applications. 2. Parallel Operation of Diesel Generators: Parallel operation involves connecting multiple diesel generators together to work in synchronization and share the electrical load. This setup offers several advantages over a single generator system, including increased reliability, scalability, and efficiency. By combining the output of multiple generators, parallel operation allows for higher power capacity, redundancy, and load sharing, ensuring a more stable and reliable power supply. 3. Benefits of Parallel Operation: a. Increased Reliability: One of the primary benefits of parallel operation is enhanced reliability. By connecting multiple generators in parallel, the system can continue to operate even if one generator fails or requires maintenance. This redundancy minimizes the risk of downtime and ensures continuous power supply, critical for applications where uninterrupted power is essential. b. Scalability: Parallel operation allows for easy scalability of the power system. Additional generators can be added to the parallel setup to increase power capacity as needed, making it a flexible solution for growing power demands or varying load requirements. c. Load Sharing: In a parallel operation setup, the electrical load is distributed evenly among the connected generators, preventing overloading and ensuring optimal performance. Load sharing helps to extend the lifespan of the generators, improve fuel efficiency, and maintain stable voltage and frequency levels. d. Fuel Efficiency: Operating multiple generators in parallel can lead to improved fuel efficiency compared to running a single large generator at partial load. By adjusting the number of generators in operation based on the load demand, fuel consumption can be optimized, resulting in cost savings and reduced environmental impact. 4. Considerations for Parallel Operation: a. Synchronization: Proper synchronization is crucial for the successful parallel operation of diesel generators. All generators connected in parallel must operate at the same voltage, frequency, and phase angle to ensure seamless load sharing and stability. Synchronization can be achieved through the use of synchronizing panels or automatic synchronizing systems that monitor and adjust the parameters of each generator. b. Control System: An advanced control system is essential for managing and monitoring the parallel operation of diesel generators. The control system should provide real-time data on the status of each generator, load distribution, fuel consumption, and other critical parameters. It should also include protection features to prevent overloading, voltage fluctuations, and other potential issues. c. Maintenance and Service: Regular maintenance and servicing are key to ensuring the reliability and performance of diesel generators in parallel operation. Maintenance tasks such as oil changes, filter replacements, and engine inspections should be carried out according to the manufacturer's recommendations to prevent breakdowns and prolong the lifespan of the equipment. d. Safety Considerations: Safety is paramount when operating diesel generators in parallel. Proper grounding, ventilation, and fire protection measures should be in place to prevent accidents and ensure the safety of personnel working around the generators. Additionally, operators should be trained on the correct procedures for starting, stopping, and monitoring the generators to minimize risks. e. Compliance and Regulations: It is important to comply with local codes, regulations, and standards governing the installation and operation of diesel generators in parallel. This includes adherence to emission limits, noise regulations, electrical codes, and other requirements to ensure the system meets safety and environmental standards. 5. Best Practices for Parallel Operation: a. Design Considerations: When designing a parallel operation system, factors such as the total power requirement, number of generators, load distribution, and future expansion should be taken into account. Proper sizing and configuration of the generators and associated equipment are essential to ensure optimal performance and reliability. b. Testing and Commissioning: Before putting the parallel operation system into service, thorough testing and commissioning are necessary to verify the synchronization, load sharing, and overall functionality of the setup. Testing should include load tests, synchronization tests, and system performance evaluations to identify and address any issues before operation. c. Monitoring and Maintenance: Continuous monitoring of the diesel generators in parallel operation is crucial to detect any deviations or abnormalities in the system. Real-time monitoring of parameters such as voltage, frequency, temperature, and fuel consumption can help identify potential problems early and take corrective actions to prevent downtime. d. Training and Documentation: Proper training of operators and maintenance personnel is essential for the safe and efficient operation of diesel generators in parallel. 500KW Diesel Generator For Sale should cover the operation procedures, maintenance tasks, troubleshooting techniques, and emergency protocols. Additionally, maintaining detailed documentation of the system layout, specifications, maintenance records, and operating procedures is important for reference and compliance purposes.  6. Case Studies and Applications: a. Data Centers: Data centers rely on uninterrupted power to ensure the availability of critical IT infrastructure and services. Diesel generators in parallel operation are commonly used as backup power sources for data centers to provide continuous power during outages and grid failures. b. Hospitals: Hospitals and healthcare facilities require reliable power for life-saving equipment, lighting, and climate control systems. Parallel operation of diesel generators is utilized in hospitals to maintain power supply during emergencies and ensure the uninterrupted operation of essential medical services. c. Industrial Plants: Industrial plants, manufacturing facilities, and production sites often have high power demands that necessitate a robust backup power system. Diesel generators in parallel operation are deployed in industrial settings to support critical processes, prevent production losses, and ensure operational continuity. d. Events and Concerts: Temporary power solutions for events, concerts, and outdoor venues often involve the parallel operation of diesel generators to meet the varying power requirements of lighting, sound systems, and other equipment. Parallel operation allows for flexible and scalable power supply to accommodate different event setups and configurations. 7. Conclusion: Diesel generators for parallel operation offer a reliable, scalable, and efficient solution for ensuring uninterrupted power supply in various applications. By harnessing the benefits of parallel operation, organizations can enhance the reliability, flexibility, and cost-effectiveness of their power systems. Proper planning, design, installation, and maintenance are essential for maximizing the benefits of diesel generators in parallel operation and ensuring long-term performance and reliability. With careful consideration of the key factors and best practices outlined in this article, organizations can leverage the power of parallel operation to meet their power needs and safeguard their operations against power disruptions.

6. Case Studies and Applications: a. Data Centers: Data centers rely on uninterrupted power to ensure the availability of critical IT infrastructure and services. Diesel generators in parallel operation are commonly used as backup power sources for data centers to provide continuous power during outages and grid failures. b. Hospitals: Hospitals and healthcare facilities require reliable power for life-saving equipment, lighting, and climate control systems. Parallel operation of diesel generators is utilized in hospitals to maintain power supply during emergencies and ensure the uninterrupted operation of essential medical services. c. Industrial Plants: Industrial plants, manufacturing facilities, and production sites often have high power demands that necessitate a robust backup power system. Diesel generators in parallel operation are deployed in industrial settings to support critical processes, prevent production losses, and ensure operational continuity. d. Events and Concerts: Temporary power solutions for events, concerts, and outdoor venues often involve the parallel operation of diesel generators to meet the varying power requirements of lighting, sound systems, and other equipment. Parallel operation allows for flexible and scalable power supply to accommodate different event setups and configurations. 7. Conclusion: Diesel generators for parallel operation offer a reliable, scalable, and efficient solution for ensuring uninterrupted power supply in various applications. By harnessing the benefits of parallel operation, organizations can enhance the reliability, flexibility, and cost-effectiveness of their power systems. Proper planning, design, installation, and maintenance are essential for maximizing the benefits of diesel generators in parallel operation and ensuring long-term performance and reliability. With careful consideration of the key factors and best practices outlined in this article, organizations can leverage the power of parallel operation to meet their power needs and safeguard their operations against power disruptions.